SMD LED 3535 620nm Red LED High Power SMD LED Diode, Surface Mount LED Chip, 3W Red LED

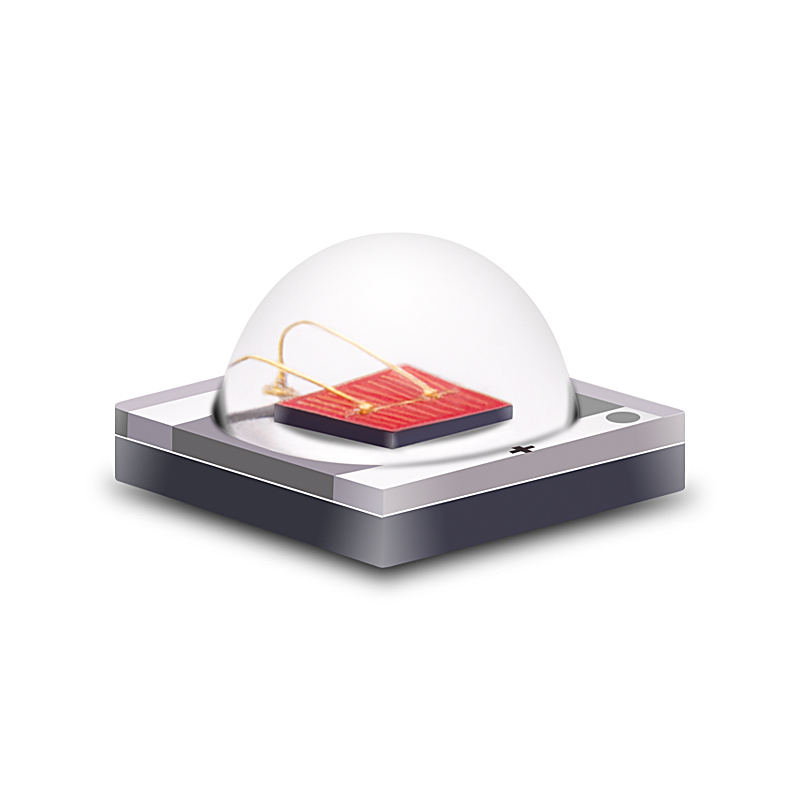

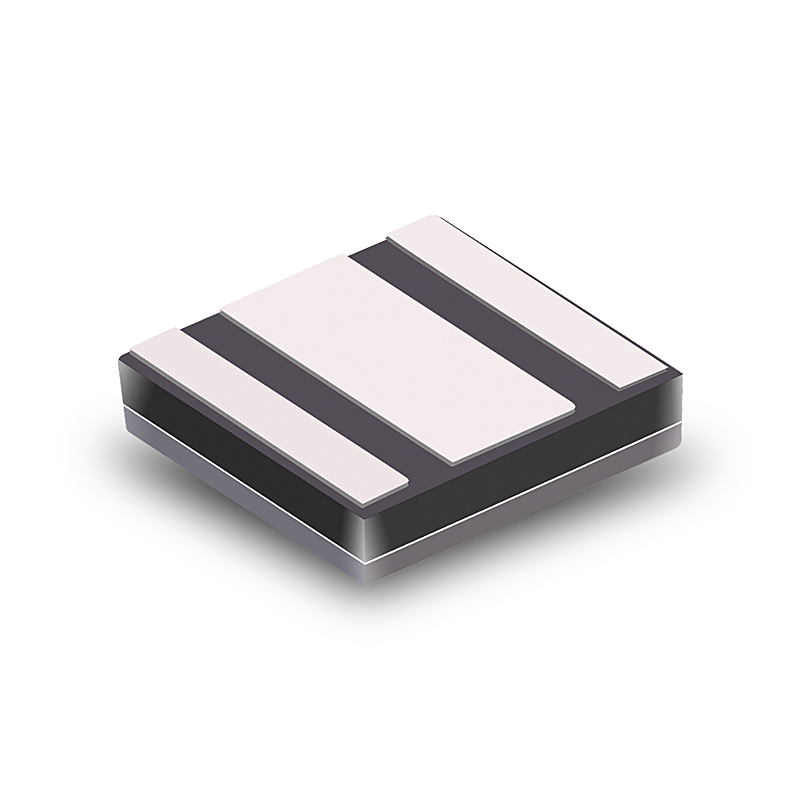

This ceramic-based, surface-mount, compact, high-brightness LED features a silicone dome lens and is designed for diverse industrial electronics applications. Its small physical dimension of 3.5 mm × 3.5 mm offers customers greater design freedom in this field, delivering up to 110 lm at 700 mA within a wavelength range of 620 nm to 625 nm.

| Dimension | 3.5 mm × 3.5 mm |

|---|---|

| Emitting Color | Red |

| Wavelength | 620–625 nm |

| Forward Current | 700 mA |

| Forward Voltage | 2.2–2.6 V |

| Luminous Flux | 90–110 lm |

| Viewing Angle | 120 ° |

| Lens Color | Clear |

| Operating Temperature | -35 °C to 85 °C |

| Packaging | Anti-static Packaging |

| Lifespan | 30,000–50,000 Hours (Typical) |

| Warranty Period | 2-Year |

Documents

Product Features

- 99.99% gold wire bonding

- High optical output

- Industry standard moisture sensitivity

- Ceramic substrate with silicone dome lens

- Low-voltage DC operated

- Lead-free reflow compatible

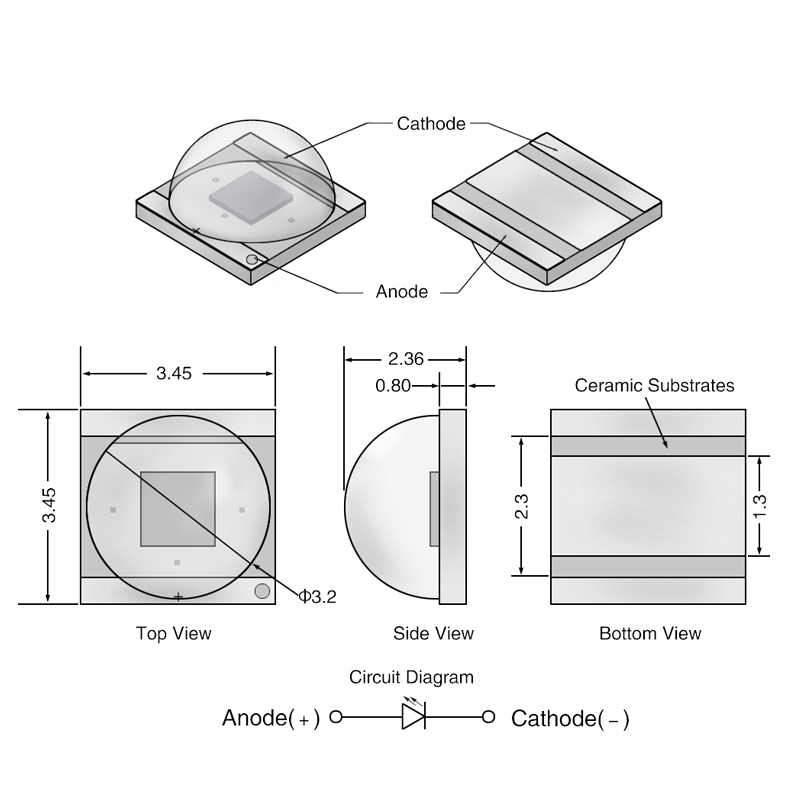

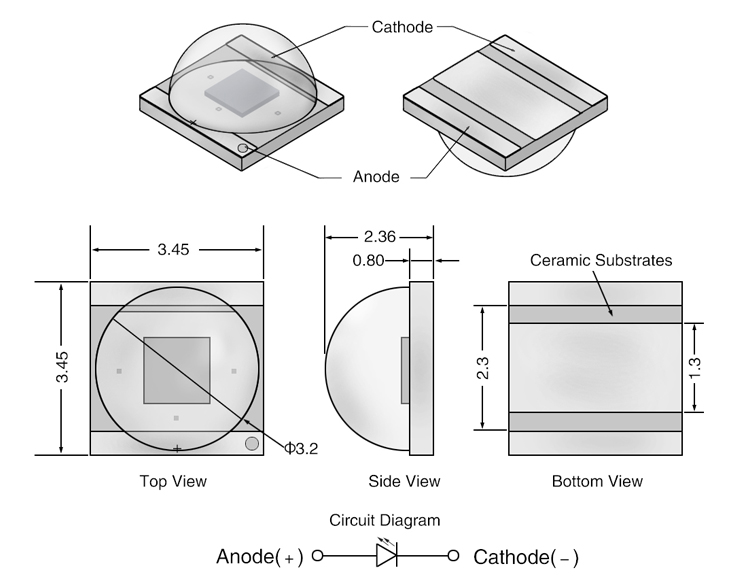

Mechanical Dimensions

- Ensure proper electrical isolation between the LED casing and the board. Crucially, never electrically connect the anode or cathode to the ceramic substrate’s thermal pad.

- Drawing not to scale.

- All dimensions are in millimeters.

- Unless otherwise indicated, tolerances are ± 0.2 mm.

- Avoid applying any force, impact, or pressure to the LED lens, as this will lead to catastrophic failure.

- To ensure continuous improvement, the product’s appearance and specifications may be updated without notice.

Flux Characteristics at 700 mA, Temperature = 25 ℃

Radiation Pattern | Part Number | Emitting Color | Luminous Flux (lm) | |

Min | Max | |||

Lambertian | SRC-13R42G-620GK | Red | 90 lm | 110 lm |

- Siro Electronics maintains a tolerance of ± 5% on flux measurements.

- To prevent damage, do not drive the device at its rated current for more than one second without an adequate heat sink.

Optical Characteristics at 700 mA, Temperature = 25 ℃

Emitting Color | Wavelength (nm) | Viewing Angle | |

Min | Max | ||

Red | 620 nm | 625 nm | 120 ° |

- Siro Electronics maintains a tolerance of ± 1 nm for wavelength measurements.

Electrical Characteristics at 700 mA, Temperature = 25 ℃

Emitting Color | Forward Voltage | |

Min | Max | |

Red | 2.2 V | 2.6 V |

- Siro Electronics maintains a tolerance of ± 0.1 V for voltage measurements.

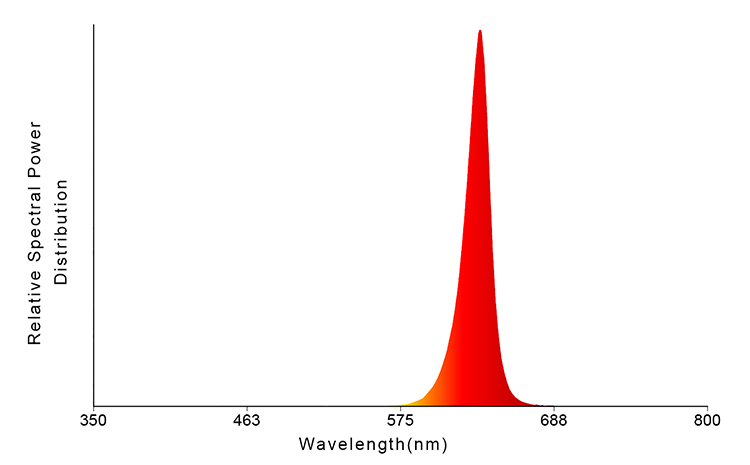

Spectral Power Distribution (SPD), Temperature = 25 ℃

Soldering Instructions

- Lead-free reflow soldering is strongly recommended. (J-STD-020 Compliant)

- When soldering Ceramic LEDs, heat may impact their electrical and optical characteristics.

- During soldering, avoid applying mechanical stress to the ceramic substrate and silicone lens at high temperatures.

- Preliminary heating should not exceed 160 °C for a maximum of 120 seconds.

- Soldering heat must not exceed 260 °C, with a maximum duration of 3 seconds.

Storage Conditions

- Store LEDs at or below 30 °C and 70% RH before opening the package.

- It is recommended that LEDs be used within one year.

- After opening the package, store LEDs in a dry box at or below 30 °C and 30% RH.

- If the moisture absorbent material (silica gel) has faded or the LEDs have exceeded their storage time, perform a baking treatment at 60 °C ± 5 °C for 48 hours.

Electrostatic Discharge (ESD) Precautions

- Static electricity or surge voltage can damage ceramic LEDs. We recommend using a wrist strap or anti-static gloves when handling them.

- Ensure your soldering iron tip is grounded and install an ionizer in areas where there is a risk of static electricity.

- All devices, equipment, and machinery must be properly grounded to ensure their safe operation. Additionally, surge protection measures are recommended for equipment that mounts ceramic LEDs.

Thermal Management

- To ensure optimal performance and longevity, the LED operating current must be determined based on the maximum ambient temperature.

- When designing the PCB, consider the heat generation of the LED.

- LEDs must be mounted on an MCPCB, a heat sink, or have a thermal pad applied.

Handing LEDs

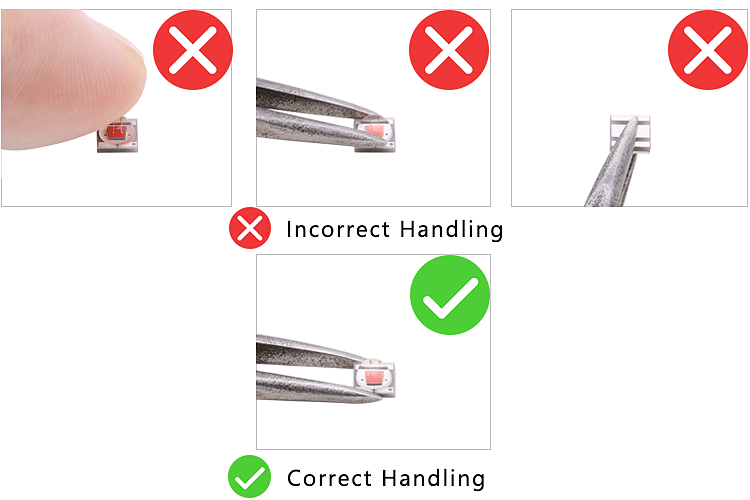

We recommend the following guidelines for handling LEDs or assemblies containing them at all times:

- When handling LEDs with tools like tweezers or nippers, avoid applying mechanical force directly to the LED’s surface.

- Do not directly touch the LED lens surface with your hands. This may contaminate the lens and affect its optical characteristics.

- Always handle LEDs from the sides. Applying force or scratching the surface can damage the molding material or break internal wires.

Need Assistance? Find Your Answers Here

Everything you need to know before you buy! Explore our FAQs on samples, payment, shipping, and how to place an order. If your query isn’t answered here, get in touch with us directly!

Absolutely. We strongly recommend sample testing to ensure they meet your requirements before a bulk order. Please reach out to us directly, and we’ll be happy to discuss further details about your sampling needs.

We are committed to supporting your evaluation. Please reach out directly to our Global Sales Team. They are ready to expedite your process by confirming sample pricing, delivery options, and technical documentation.

By managing our production in-house, we can offer flexible MOQ options tailored to your project. Our main focus is on providing effective solutions that perfectly align with your specific needs.

If you are ready to proceed, please reach out to us directly. Our Sales Team will get back to you within 24 working hours and will personally guide you through the order placement process.

For regular orders, we primarily accept T/T (Telegraphic Transfer) payments. Smaller trial orders can also be paid via PayPal.

Customs duties and import taxes may apply depending on your country’s regulations. These costs are not included in the product price and would typically need to be covered by you upon delivery.

Our LED chips generally have a lifespan of 30,000 to 50,000 hours, depending on operating conditions. Therefore, the product should be assembled under the guidance of a technician.

All of our LEDs are manufactured in a dust-free workshop, adhering to industry-standard procedures. Each product comes with a 2-year warranty, ensuring your peace of mind.

The typical lead time for our LEDs is about 10 days from production to delivery. We will provide a detailed schedule upon your order confirmation to guarantee prompt delivery.

For your convenience, we ship all LEDs via leading couriers like DHL, FedEx, and UPS. While transit times may vary by destination, you can typically expect your delivery within one week.

Absolutely! We’re here to help create it. Our engineering team provides tailor-made solutions for chip design, spectrum tuning, and specialized packaging to meet the unique specifications of each project.

To ensure optimal performance, we provide full support from pre-sales to post-sales, including datasheets and expertise in integration, thermal management, and failure analysis.