Your Trusted LED Partner and Optoelectronics Services Provider

Providing reliable, cutting-edge LED solutions for industries worldwide.

You can count on us to deliver the best materials for your technological requirements.

Meet Us and Our LED Solutions

By merging innovative LED encapsulation technology with outstanding customer service, we provide a wide array of LED options, crafted from varied material grades to suit diverse budgets and requirements.

At Siro Electronics, we take pride in being a prominent supplier of Light Emitting Diodes, excelling in LED encapsulation technology. With extensive experience and a dedication to excellence, we’ve earned a reputation for delivering outstanding, dependable LED solutions customized to our clients’ distinct needs. Our mission is to provide innovative LED Chip products that boost efficiency and performance across global industries.

We supply a varied array of products and services, including LEDs, printed circuit boards (PCBs), related accessories, and tailored lighting solutions. Catering to vital industries like Plant Growth, Automotive, Scientific and Medical Instrumentation, Video Surveillance, Spectroscopy, and Consumer Electronics, we’re committed to upholding exceptional quality and performance standards. By blending technological innovation with attentive service, we aim to help clients make their projects successful across all industries.

What Set Us Apart from the Competition

From cost-effective, varied, and innovative solutions to tailored personal services, we’re dedicated to ensuring promised quality and supporting you in achieving your goals with unwavering reliability every time.

Directly Manufactured

This empowers us with absolute and total control over the entire production process, guaranteeing consistent, superior outcomes from start to finish every time.

Customization

Regardless of your application, we can meet your specific needs by tailoring LED bead wavelengths and encapsulation packages, supporting your flexible new prototype development.

Genuine Materials

Raw materials, sourced via trusted supply chains from reputable suppliers, maintain consistently exceptional functionality and unwavering reliability, with full traceability records.

Contract Manufacturing

OEM/ODM partnerships equip distributors to broaden their market presence, boost market share, and enhance competitive advantage effectively.

Free Sample

Sample testing is highly and universally recommended to confirm that the LED specifications fully meet your expectations before placing a bulk order.

One-Stop Sourcing

One-stop LED and PCB solutions, providing expert, flexible support from selection to production, truly helping engineers and procurement teams work efficiently.

Global Delivery

Through our extensive network of logistics partners, trackable shipping is comprehensively and instantly available to the vast majority of countries across the world.

24/7 Service

Prompt and thorough customer service, including specialized technical support, pre-sales consultation, and shipment coordination. Contact us today for details.

Something You Want to Discuss? We're Here to Talk.

How We Work: Our Manufacturing Process Explained

From raw materials to finished products, our manufacturing process reflects extensive experience, technical skill, and a pursuit of perfection. Discover how we create each Light Emitting Diode.

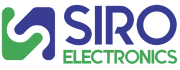

The die bonding process commonly involves depositing adhesive accurately onto the substrate, extracting the wafer material from the blue film, aligning it with exceptional precision, and then placing it securely onto the adhesive to ensure structural integrity.

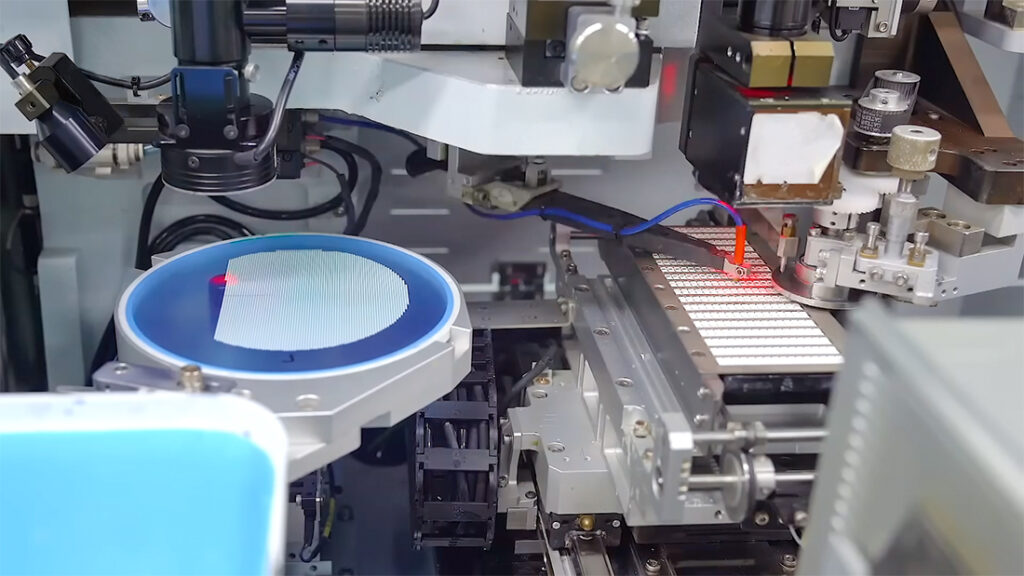

Wire bonding is an essential step in LED packaging, where ultra-fine gold wires are precisely utilized to establish dependable electrical links between the bonding pads on the wafer surface and the matching pads on the substrate or lead frame, guaranteeing superior functionality.

Injecting gel to create an external protective coating, where the wafer, gold wire, and other parts are encased in a durable layer of epoxy or silicone. This procedure shields the elements from environmental hazards such as moisture, dust, and mechanical strain.

The baking phase entails exposing the encapsulated LED packages to precisely controlled heat. This pivotal step hardens the encapsulant, guaranteeing that the LED chip remains firmly enclosed and that the intended package shape is perfectly formed.

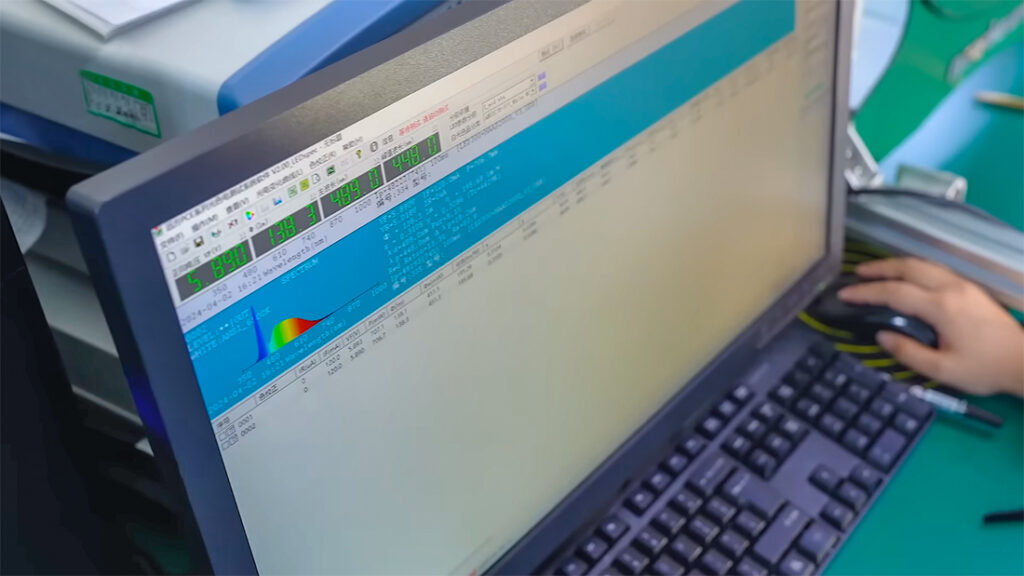

Light sorting and color binning ensure light output consistency across a batch of LEDs. This process involves measuring the optical characteristics of each LED and grouping them into different bins based on their wavelength, color temperature, and luminous intensity.

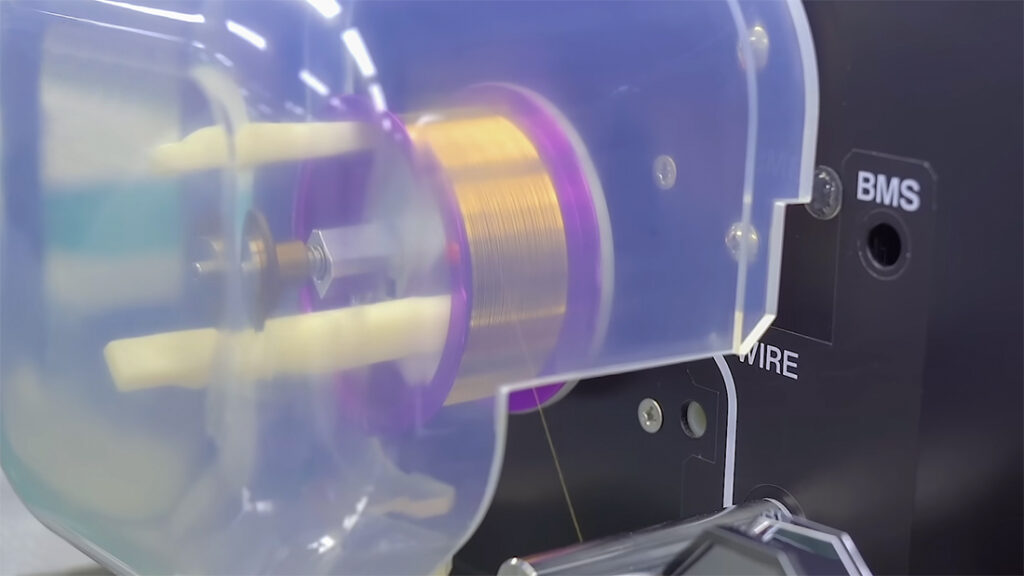

Packaged LED beads using tape and reel for efficient handling, sealed them in anti-static bags to prevent damage, and attached labels with key specifications like voltage and wavelength details, preparing the finished products for logistics and global shipment.

How We Ensure: Our Quality Commitment Demonstrated

From material sampling to aging tests, our detailed quality system employs skilled expertise and modern technology to deliver reliable LED diodes for you. Explore the quality control at every step.

Before production, we meticulously sample and evaluate raw materials, like wafers and substrates, confirming adherence to stringent industry standards to lay a robust foundation for consistently producing high-quality, dependable LED components.

Throughout production, we carefully examine semi-finished LEDs for imperfections, maintaining rigorous quality control in each phase to ensure every step meets our exact manufacturing standards, offering reliable, premium LED solutions.

Before packaging, we verify finished products against tough quality guidelines, testing each order’s LEDs with an integrating sphere for voltage, luminous flux, wavelength, and CRI to ensure all photoelectric parameters meet client needs precisely.

For every order, we perform aging tests on a fixed product sample ratio, evaluating long-term durability, stability, and performance under real-world conditions to ensure the LEDs' reliability and build strong customer confidence continuously.

Need Help? Your Questions Answered

Discover our FAQs to resolve critical questions about premium products and support services, inspiring your strategic business decisions. If you can’t find what you’re seeking, let’s connect directly!

We highly recommend sample testing to validate they meet your requirements before ordering in bulk. Please contact us directly to receive samples that match your specific needs.

All our LED chips are manufactured under strict quality control and are fully compliant with international standards, including RoHS, REACH, and other relevant industry certifications.

We take confidentiality seriously and are happy to sign NDAs (Non-Disclosure Agreements) to guarantee your designs, technical details, and intellectual property remain fully protected.

The typical production-to-delivery cycle for our LEDs averages around 10 days. To guarantee prompt delivery, we’ll provide a detailed, precise schedule upon your order confirmation.

We ship LEDs swiftly via trusted couriers like DHL, FedEx, and UPS to ensure reliable, efficient service. Delivery time varies by your location, typically arriving within one week.

Absolutely! We offer customized solutions in chip design, spectrum tuning, and packaging, ensuring our LEDs meet the precise needs of your project.

Explore Our LED Solutions

Discover our portfolio of advanced LED components tailored to your sector’s needs.