The Rise of IR LED Chips in Industry

Infrared (IR) LED chips drive innovation in security, healthcare, consumer electronics, and automotive sectors. Operating in the 700nm–1050nm range, with key wavelengths at 740nm, 850nm, and 940nm, they power functions like night vision, biometric authentication, and gesture recognition. These chips deliver precise, energy-efficient, and versatile solutions, often discreet or nearly invisible, making them vital to modern technology.

With 15 years of optoelectronic expertise, Siro Electronics spearheads the infrared revolution, supplying high-quality IR LED chips worldwide. This blog explores IR LED technology, its diverse applications, and strategies for choosing the right chip. Whether for security systems, medical devices, or automotive night vision, we offer insights and support to ensure your success.

What Are IR LED Chips? Technology Basics

Infrared (IR) LED chips are semiconductor devices engineered to emit infrared light within the 700nm to 1050nm wavelength range. These chips are integral to various applications where visible light is ineffective or undesirable, such as night vision systems, security cameras, and medical devices. While many IR LEDs emit light that is invisible to the human eye, some can produce a faint red glow visible under certain conditions. Regardless, all IR LEDs can be detected by specialized sensors and cameras designed to capture infrared radiation.

How Do IR LED Chips Work?

The basic principle behind IR LED chips is the conversion of electrical energy into light. The semiconductor material used in the chip undergoes electroluminescence, meaning it emits infrared light when a current passes through it. This process is similar to that of visible light LEDs, but the emitted light in this case is outside the visible spectrum. The most commonly used wavelengths for IR LEDs are 740nm, 850nm, and 940nm, each offering specific advantages for different applications.

- 740nm: Often used for applications requiring slightly visible infrared light, providing a balance between invisibility and detection range.

- 850nm: Widely used in security cameras and surveillance systems, offering a good balance of range and efficiency.

- 940nm: Typically used when complete invisibility is required, such as for covert surveillance.

Types of IR LED Chips

IR LEDs come in several configurations to meet various needs and performance requirements:

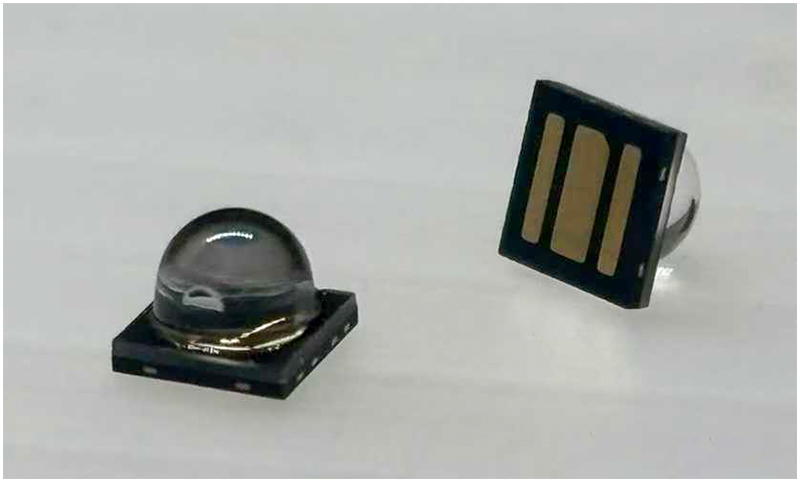

1. SMD (Surface-Mounted Device): These are compact and versatile, widely used in consumer electronics and low-power applications. They are ideal for integration into smaller devices like sensors and security cameras.

2. High-Power LED: Designed for applications that require high-intensity infrared light, such as long-range surveillance, security cameras, and industrial monitoring systems. They offer greater luminous output and can be used in outdoor environments or high-demand applications.

3. Ceramic LED: Known for their ability to withstand high temperatures, ceramic IR LEDs are perfect for applications that require high thermal resistance. They are commonly used in automotive, industrial machinery, and high-power infrared applications.

Key Parameters of IR LED Chips

When selecting an IR LED chip, several important parameters should be considered:

- Radiation Intensity (mW): The amount of infrared power emitted by the chip. Higher intensity is crucial for longer-range applications like night vision and security systems.

- Wavelength: As mentioned, different wavelengths serve different purposes, from longer-range detection to shorter-range, high-efficiency use cases.

- Beam Angle (30°-120°): The beam angle affects how the emitted light is spread. A narrower angle (e.g., 30°) concentrates the light for longer distances, while a wider angle (e.g., 120°) offers broader coverage, suitable for monitoring larger areas.

Understanding these basic technical aspects of IR LED will help ensure that the correct chip is chosen for your specific application, optimizing performance and reliability in critical systems. Whether for security, medical imaging, or automotive solutions, selecting the right component is key to achieving superior results.

Key Applications of IR LED Chips Across Industries

Infrared (IR) LED chips revolutionize industries by powering advanced technologies that leverage infrared light for enhanced performance, efficiency, and safety. The following sections highlight their key applications across diverse sectors, demonstrating their versatility and critical role.

1. Security and Surveillance

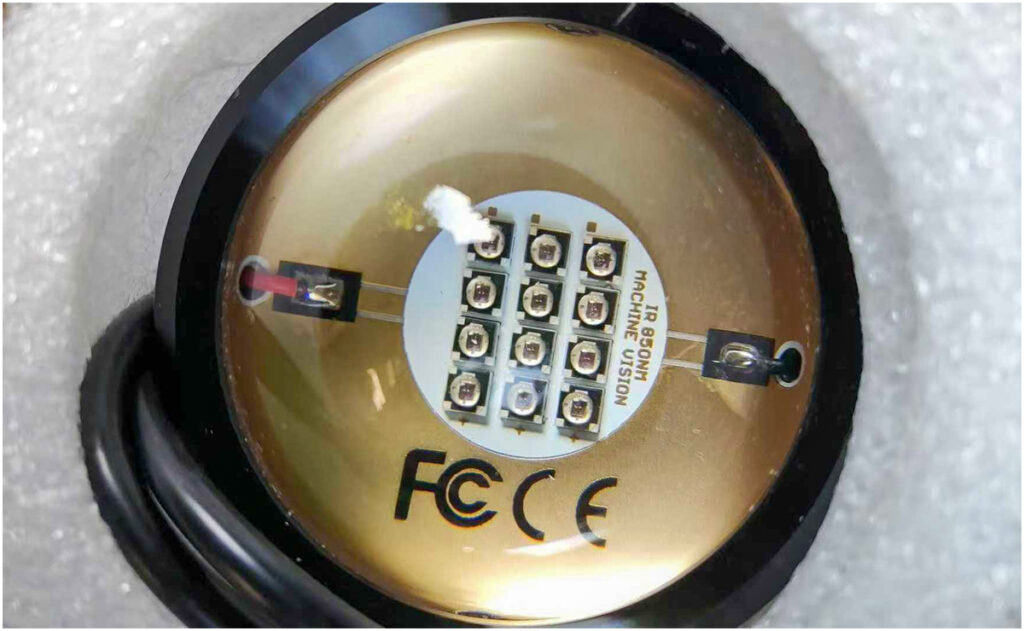

IR LED chips are essential for security and surveillance, especially in night vision applications. Cameras with IR LEDs enable clear imaging in complete darkness by emitting infrared light, which objects reflect and the camera’s sensor captures.

- Commonly used in security cameras, 850nm IR LEDs deliver sharp, high-quality images in low-light or dark settings. They support detailed surveillance in areas like parking lots, warehouses, and perimeter fencing, balancing detection range with discreet operation for unobtrusive, high-performance night vision.

- As demand for 24/7 surveillance grows, IR LED technology enhances the reliability and effectiveness of security systems, making them vital for protecting public and private spaces.

2. Medical Applications

IR LED chips power a range of medical diagnostic and therapeutic devices. Pulse oximeters, for instance, use 940nm IR LEDs to non-invasively measure blood oxygen levels by emitting infrared light through the skin. The light’s varying absorption, based on blood oxygenation, is analyzed to calculate oxygen saturation.

- In infrared therapy, 940nm IR LEDs penetrate deep into tissues, promoting healing, reducing inflammation, and enhancing circulation. These LEDs are widely used in pain management and rehabilitation for conditions like arthritis or muscle injuries.

IR LEDs are thus vital for delivering innovative diagnostic and therapeutic solutions in modern healthcare.

3. Consumer Electronics

In consumer electronics, IR LED chips power devices using infrared communication and detection technologies. Remote controls, a primary application, rely on IR LEDs to send signals to devices like TVs, air conditioners, and appliances.

- Compact and energy-efficient SMD IR LEDs are ideal for remote control systems, facilitating seamless wireless communication and enhancing user experience in everyday products.

- Smart home sensors also leverage IR LEDs for motion detection, proximity sensing, and automated lighting. By emitting infrared light, these sensors detect people or objects without visible light, creating efficient, intuitive smart home environments.

4. Automotive Industry

In the automotive industry, IR LED chips are vital for driver assistance systems, enhancing safety and functionality. Night Vision Systems, a primary application, uses IR LEDs to improve visibility in low-light conditions.

- These systems deploy high-power 850nm IR LEDs to illuminate roads, allowing cameras and sensors to detect pedestrians, animals, and obstacles invisible at night. This technology significantly boosts driver safety in challenging conditions like fog, rain, or darkness.

- Driver Monitoring Systems (DMS) leverage IR LEDs to track driver behavior. By illuminating the driver’s face in low light, they enable cameras to monitor eye movements and facial expressions, detecting fatigue or distraction to strengthen advanced driver-assistance systems (ADAS).

5. Industrial Applications

IR LED chips play a pivotal role in industrial settings, excelling in machine vision and thermal imaging applications.

- In manufacturing and automation, machine vision systems harness IR LEDs to monitor production lines, ensuring quality and detecting defects. By emitting infrared light, these systems reveal irregularities invisible under standard lighting, providing reliable illumination for precise inspections in low-light conditions.

- IR LEDs empower thermal cameras to detect temperature variations in machinery, electrical components, and pipelines. These cameras identify overheating or potential failures, enhancing efficiency and reducing downtime in industrial operations.

- In robotics, IR LEDs enable object recognition, navigation, and obstacle avoidance. Paired with IR sensors, they allow robots to interact seamlessly with their surroundings, advancing automation and precision in manufacturing and logistics.

IR LED chips fuel innovation across sectors, from security and healthcare to consumer electronics, automotive safety, and industrial automation. With expanding applications and advancing technology, IR LEDs promise more efficient, reliable, and cost-effective solutions, revolutionizing industries.

Technical Considerations for Choosing IR LED Chips

Selecting IR LED chips for diverse applications requires evaluating key technical factors to ensure peak performance. These include wavelength, power and efficiency, packaging, and viewing angles. Understanding these elements ensures the chosen IR LED chip aligns with specific application needs.

1. Wavelength Selection: 740nm vs. 850nm vs. 940nm

The wavelength of an IR LED chip critically shapes its performance, varying by application. Common wavelengths—740nm, 850nm, and 940nm—each serve distinct purposes:

- 740nm: In the near-infrared range, this wavelength balances visibility and performance, offering a wide detection range. Detectable by select cameras, it’s ideal for surveillance needing subtle illumination.

- 850nm: The most widely used wavelength, 850nm, balances detection range and low visibility. Perfect for night vision cameras and security systems, it ensures reliable detection without visible light, ideal for low-light monitoring.

- 940nm: Nearly invisible to the human eye, 940nm excels in stealth applications like covert surveillance and infrared therapy. With a shorter detection range than 850nm, its deeper penetration suits medical and industrial applications.

2. Power and Efficiency: 1W vs. 10W

An IR LED’s power shapes its brightness, heat dissipation, and efficiency, critical factors tailored to specific applications:

- 1W LEDs: Compact and energy-efficient, these LEDs shine in low-power uses like remote controls and sensors. Their long lifespan and suitability for space-constrained devices make them ideal for energy-saving designs.

- 10W LEDs: Designed for high-intensity applications such as industrial machinery, surveillance cameras, and night vision systems, these LEDs deliver powerful illumination. Generating significant heat, they require robust thermal management to maintain optimal performance and durability.

Selecting low-power or high-power LEDs hinges on the application’s energy needs, brightness, and detection range requirements.

3. Packaging and Viewing Angle: SMD vs. Wide-Angle Options

An IR LED chip’s packaging and viewing angle critically influence its light distribution:

- SMD (Surface-Mounted Device): Compact and efficient, SMD IR LEDs shine in devices like remote controls and smart home sensors. Cost-effective and ideal for space-constrained designs, they provide a narrow viewing angle for precise, directional illumination.

- Wide-Angle IR LEDs: Vital for applications requiring broad coverage, such as security cameras and industrial inspection, these LEDs emit infrared light across a wide angle. They ensure uniform illumination in large areas like warehouses, parking lots, and monitoring zones, enabling clear imaging and effective low-light surveillance.

Selecting the optimal IR LED chip involves assessing key factors—wavelength, power, packaging, and viewing angle—that drive performance. Wavelength must match sensor sensitivity, power affects intensity and energy use, packaging impacts durability and integration, and viewing angle determines light spread. For surveillance, medical, or consumer electronics projects, informed choices on these factors enhance performance and efficiency.

Common Challenges and How to Overcome Them

Working with IR LED chips can present challenges during selection and implementation. Understanding these obstacles and their solutions ensures projects run smoothly and maximizes the performance of IR LED components.

1. Incorrect Wavelength Selection

A common challenge is choosing the wrong wavelength for an application. For instance, 850nm IR LEDs suit general night vision in surveillance systems, but covert operations requiring invisibility demand 940nm LEDs. Incorrect wavelength selection can cause poor performance or unwanted visibility.

Solution: Evaluate your application’s needs and consult your LED supplier to select the right wavelength. Testing samples in real-world conditions ensures the chosen wavelength meets your requirements.

2. Insufficient Heat Dissipation

Poor thermal management is a frequent issue that compromises IR LED longevity and efficiency. Ineffective heat dissipation triggers thermal runaway, reducing chip lifespan below 50,000 hours. High-power IR LEDs generate substantial heat and risk premature degradation without proper cooling.

Solution: Ensure the LED’s thermal resistance matches its power requirements. Select suitable heat sinks or ceramic-based IR LEDs with superior heat dissipation. Test thermal performance with samples to confirm reliability.

3. Compatibility Issues with Drivers

Driver compatibility, often overlooked, is vital for IR LED performance. Mismatched voltage or current ratings between the LED and driver can lead to improper function, reduced efficiency, or complete failure.

Solution: Confirm that the LED’s electrical specifications, including voltage and current, align with the driver’s requirements. Manufacturers provide detailed datasheets for each LED model to verify these parameters. If uncertain, consult your supplier to ensure all components are fully compatible.

The key to overcoming these challenges lies in careful planning, thorough testing, and collaboration with your LED supplier. By considering factors such as wavelength selection, thermal management, and driver compatibility, you can ensure the optimal performance of your IR LEDs and avoid costly mistakes down the line.

How Siro Electronics Supports Your IR LED Journey

With over 15 years of expertise, we deliver high-quality IR LED solutions to global industries, including security, medical aesthetics, and consumer electronics. Our deep knowledge of IR technology enables us to provide customized solutions that address each sector’s unique needs, ensuring efficient and reliable project outcomes.

Customized Services

We offer comprehensive support throughout your IR LED journey. Our services include:

- Pre-Sales Consultation: Our expert engineers guide you in selecting optimal IR LED chips customized for applications like surveillance, medical devices, or automotive systems.

- Technical Support: We supply detailed datasheets and assist in integrating LED chips, ensuring compatibility with drivers and thermal management needs.

- After-Sales Service: We deliver swift issue resolution to keep projects on track and maintain consistent performance.

Commitment to Quality

Quality is central to us. We uphold strict standards, including ISO 9001 certification, ensuring every product undergoes rigorous testing. Our two-year warranty on all LED chip products provides peace of mind and confidence in your investment.

Sample Testing

Recognizing the uniqueness of each application, we encourage testing IR LED samples in real-world conditions. Assess critical metrics—radiation intensity, wavelength, and thermal performance—to ensure the LEDs fulfill your project’s requirements.

Embrace IR LED Innovation Today

IR LED technology transforms industries with its blend of efficiency, compact design, and versatility. From surveillance and medical diagnostics to automotive and industrial applications, IR LEDs fuel innovation across sectors. Advancing technology drives cost reductions and enhanced performance, making these components more accessible and valuable for both large-scale and niche projects.

The future of IR LEDs shines bright, with trends like AI-integrated infrared sensors enabling smarter, more efficient systems. Embracing these innovations will give your business a competitive edge.

Act now! Contact us at info@siroelectronics.com or visit our Contact page to explore your IR LED needs. We’re here to guide you every step of the way, ensuring optimal solutions.