Why Choosing the Right LED Chips Matters

LED chips are at the core of modern lighting and technology, driving industries such as automotive, plant growth, consumer electronics, and more. Choosing the right chip is essential for ensuring optimal performance, energy efficiency, and longevity. On the other hand, poor selection can result in poor light output, inaccurate color or temperature representation, and reduced lifespan, leading to costly long-term maintenance and negatively affecting the project’s overall budget and timeline.

With over 15 years of expertise in optoelectronics, we are well-versed in these challenges. As a trusted supplier of LED components, we’ve supported industries worldwide in achieving success through customized solutions. In 2025, as LED technology advances with higher efficiency and new applications, selecting the right LED chip will be increasingly vital.

This comprehensive guide aims to equip professionals with the knowledge necessary to navigate the complexities of LED chip selection. From understanding key parameters to avoiding common pitfalls, we’ll equip you with practical insights for 2025 and beyond. By the end of this tutorial, you will be well-positioned to select the ideal LED chip that aligns with your specific requirements and objectives.

Understanding LED Chips: Basics and Key Features

LED chips are semiconductor-based light-emitting components that form the core of modern lighting systems. They generate light through the electrical excitation of light-emitting materials, providing excellent energy efficiency with a long lifespan. Choosing the right LED chip is essential to achieving optimal lighting effects and performance.

Types of LED Chips

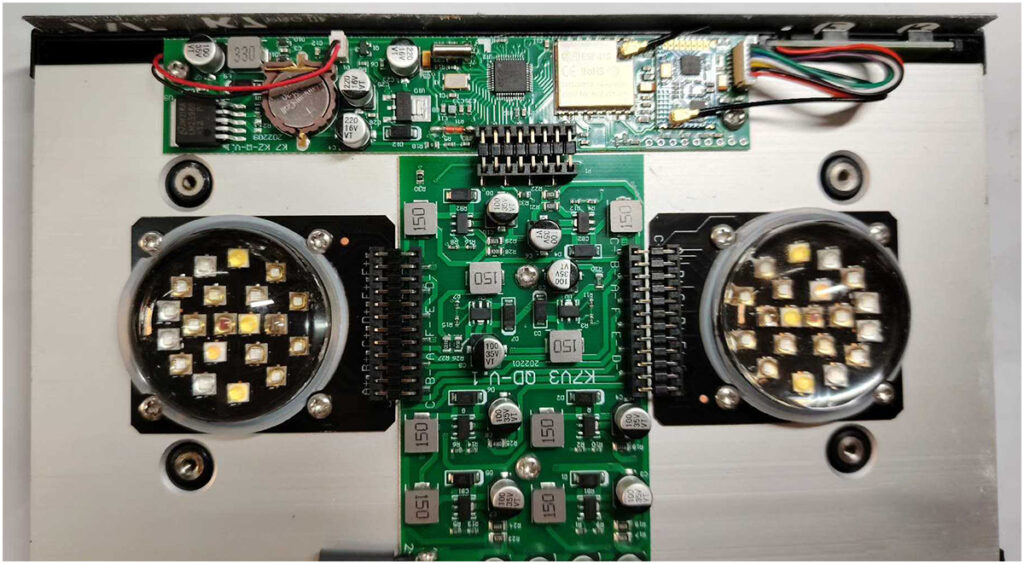

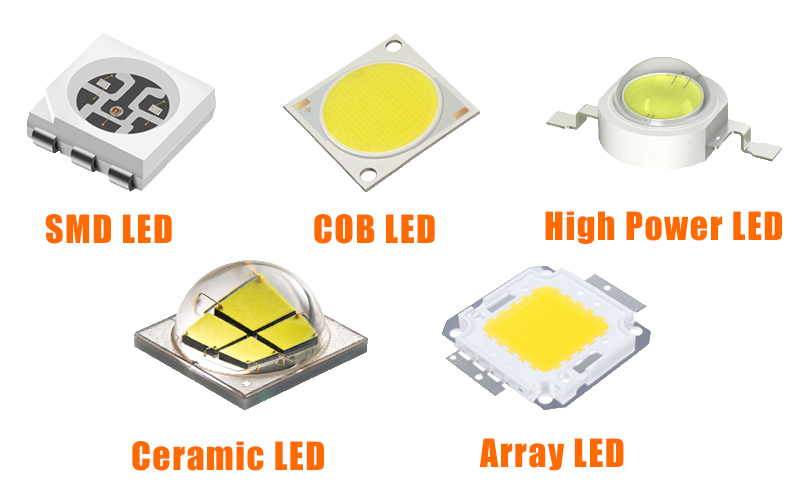

Each type serves unique applications:

- SMD (Surface-Mounted Device): Compact and versatile, making them ideal for applications such as signage and indoor lighting.

- COB (Chip-on-Board): Multiple LED wafers mounted closely together, delivering high luminous flux and uniform light output, making them perfect for applications like floodlights and high-bay lighting.

- High-Power LED: Engineered for applications that demand intense brightness, including entertainment lighting and street lighting.

- Ceramic LED: Utilize ceramic substrates for superior heat dissipation, making them ideal for compact, high-performance applications.

- Array LED: Multiple LED wafers arranged in a matrix, providing enhanced brightness, color mixing capabilities, and enabling flexible zonal (RGB) control designs.

Key Parameters Explained

Seven key factors influence LED chip selection:

1. Power Rating

- Measured in Watts, options range from 0.2W to 100W

- Determines the capacity of the light output

2. Forward Voltage and Forward Current

- Common ranges include 3V at 20mA to 36V at 3500mA

- Affects the driver design

3. Luminosity and Luminous Efficacy

- Given in lumens per Watt (lm/W)

- Indicates the efficiency of light output; higher values signify more light per watt, leading to energy savings

4. Wavelength Range

- LED wavelength, for example, 620-630nm corresponds to red, while 520-530nm corresponds to green

- RGB combines red (620nm), blue (460nm), and green (520nm) in a single package

5. Color Temperature

- Measured in Kelvin (K), with options like warm white (3000K), neutral white (4000K), and cool white (6000K)

- Defines the light’s warmth or coolness; incorrect choices can negatively impact the user experience

6. Color Rendering Index (CRI)

- Measures the ability of light to reveal the true colors of objects; a higher CRI (80+) indicates better color accuracy. But 90+ is vital for retail boutiques to display vibrant clothing colors or art galleries to preserve artwork fidelity.

7. Thermal Management

- Effective heat dissipation is essential for preserving LED performance and extending lifespan. Excessive heat can reduce luminous efficacy, alter color temperature, and shorten lifespan. Proper thermal design requires selecting suitable accessories, heat sinks, and ensuring optimal thermal resistance to manage heat efficiently.

Why These Features Matter

Understanding these parameters ensures the selection of LED chips that align with specific application requirements, whether it’s for energy efficiency, color accuracy, or brightness. For example, a high CRI is essential in retail environments to accurately display product colors, while high luminous efficacy is crucial for street lighting to minimize energy consumption. Additionally, effective thermal management prevents overheating, ensuring consistent performance and extending the lifespan of the LED chips.

Step-by-Step Guide to Selecting LED Chips

Selecting the right LED chip for your project can be complex, but a structured approach simplifies the process. This 2025 guide outlines five practical steps to ensure you choose LED chips that meet your needs, from plant lighting to industrial applications, with insights from our 15 years of expertise.

Step 1: Define Your Application Needs

Begin by identifying the purpose of your project. Are you designing grow lights, consumer electronics, or art gallery lighting? Each application requires specific chip characteristics. For plant growth, you’ll need chips with red and blue wavelengths (660nm and 450nm) to maximize photosynthesis. Clearly defining the use case helps narrow down chip options, such as ceramic LEDs for high-intensity grow lights or SMDs for flexible strips.

Step 2: Determine Technical Specifications

Next, match the chip to your technical requirements. Key specs include:

- Power: 1W could be High-Power LED or Ceramic LED, 50W could be COB or Array LED

- Forward Voltage and Current: For driver interface compatibility

- Color Range: Select wavelengths or color temperatures, like 3000K for warm restaurant ambiance or 660nm to boost horticultural plants

- LED Package Size: Smaller packages (e.g., 3.5×3.5mm) suit compact designs

- Budget and Cost: Find a balance between the performance capabilities and the cost of the LED chip

Step 3: Assess the Impact of Environmental Conditions

Consider the operating environment. High temperatures, such as those in automotive engine bays, require ceramic LEDs with thermal resistance under 5°C/W. Humid environments, like greenhouse lighting, demand IP65-rated sealing to protect against moisture. A mismatch between the environment and the LED design can reduce chip lifespan from 50,000 hours to under 10,000.

Step 4: Balance Budget and Performance

Weigh cost against performance. High-CRI (90+) chips enhance color accuracy for retail display lighting, ensuring products are illuminated with true-to-life colors, but they come at a 20-30% higher price than CRI 80 alternatives. Similarly, high-efficiency chips (150 lm/W) reduce energy consumption but raise initial costs. For budget-conscious projects, such as street lighting, ceramic LEDs provide a cost-effective balance without compromising brightness.

Step 5: Sample Evaluation

Testing LED chip samples under real-world conditions is crucial before bulk orders. Request samples from suppliers to assess key performance metrics, such as brightness (e.g., 150 lm/W for high-power LEDs in streetlight prototypes), color consistency, heat dissipation, lifespan, and driver compatibility. For example, a client tested ceramic LED samples in a 70°C industrial oven, verifying stability over 10,000 hours. We provide samples with comprehensive datasheets to support informed decision-making.

These five steps empower you to select LED chips that optimize efficiency, durability, and project success.

Common Mistakes to Avoid When Choosing LED Chips

Selecting the right LED chip is crucial for ensuring optimal performance and longevity in your lighting applications. However, several common mistakes can lead to deficient results and increased costs. Here’s a guide to help you avoid these pitfalls:

1. Ignoring Color Rendering Index (CRI)

The CRI (Color Rendering Index) measures how accurately a light source displays colors compared to natural light. Choosing LEDs with a low CRI can lead to poor color accuracy, which is especially problematic in environments like retail spaces or art galleries where true color representation is crucial. To ensure vibrant and accurate color rendering, always opt for LEDs with a CRI of 80 or higher.

2. Prioritizing Price Over Other Factors

While it may be tempting to choose cheaper LED chips, they often come with trade-offs such as reduced lifespan and lower efficiency. This can lead to higher maintenance costs and more frequent replacements. Investing in high-quality LEDs may have a higher initial cost but offers better energy efficiency and a longer operational life, ultimately saving money in the long run.

3. Overlooking Thermal Management

Effective heat dissipation is vital for maintaining the performance and lifespan of LED chips. Poor thermal management can lead to overheating, which may cause LEDs to dim, change color, or fail prematurely. Ensure that the chosen LEDs have adequate heat sinks or cooling mechanisms to manage heat effectively. For instance, LEDs with ceramic substrates or integrated cooling designs offer superior thermal performance.

4. Failing to Consult with Suppliers

Neglecting to engage with LED suppliers can result in selecting chips that are unsuitable for your specific application. Suppliers can provide valuable insights into product specifications, compatibility, and performance under various conditions. Consulting with them ensures that you choose the right LED chips tailored to your needs, avoiding potential issues down the line.

How Siro Electronics Supports Your LED Chip Selection

Choosing the right LED chip is crucial for the success of your project, and with 15 years of experience in LED packaging, we’re your trusted partner. From expert consultation to sample production, our comprehensive support ensures you select the perfect chips for your applications, whether in automotive, horticulture, or medical devices, both now and in the future.

Proven Expertise and Global Reach

With nearly 15 years of experience, we have been a trusted provider of customized LED solutions, serving industries worldwide. Our RGB LED chips power entertainment and stage lighting in Europe, enabling vibrant color mixing, while boosting greenhouse yields in North America by 15% with precise red-blue wavelengths (660nm, 450nm). Drawing on our extensive expertise in optoelectronics, we confidently guide clients through the complexities of chip selection.

Customized Services for Every Stage

We provide end-to-end support:

- Pre-Sales Consultation: Our engineers assess project requirements and recommend the ideal chips, such as COB for high-intensity theater lighting or SMD for compact horticulture lighting solutions.

- Technical Support: We provide comprehensive datasheets to ensure chips are compatible with driver voltages (e.g., 3.2V at 350mA) and meet thermal specifications.

- After-Sales Service: We ensure swift resolution of any issues to keep your projects on schedule. For instance, we assisted a CCTV equipment manufacturer in optimizing their infrared solution, boosting image quality by 20% and improving their customers’ overall experience.

Uncompromising Quality Control

Quality is at the core of everything we do. From raw material sampling to order aging tests, our stringent quality control process—outlined on our About page—ensures zero defects. We comply with ISO 9001 standards, conducting in-process inspections and pre-packaging verifications to guarantee long-lasting performance. For example, a textile industry client trusted our CRI 90+ full-spectrum chips to display fabric raw materials accurately, effectively preventing the mixing of similarly colored fabrics during the garment manufacturing process due to ambient lighting discrepancies.

Two-Year Warranty for Confidence

Every product includes a two-year warranty, covering defects and performance issues. This ensures the reliability of your projects and applications, including those in critical sectors like automotive lighting and medical devices. In the event of a chip failure, we provide prompt replacements to minimize downtime and keep your project on schedule.

Encouraging Sample Testing

We prioritize your success and recommend sample testing to verify performance. Request samples to assess brightness (e.g., 150 lm/W for High-Power chips) and color accuracy (CRI 90+) under real-world conditions, such as high-temperature and high-humidity greenhouses.

A commercial lighting client tested SMD samples for retail store illumination. The full-spectrum technology provided an excellent visual appearance for the store’s products in the display cases, immediately increasing the client’s engagement by 10%.

A medical aesthetics clinic has confirmed that ceramic LEDs exhibit remarkably good stability even in hot and humid sauna environments, having accumulated nearly 30,000 hours of operation with good durability.

We provide comprehensive datasheets and foster open communication to refine your selection.

Start Choosing Your LED Chips Today

Selecting the right LED chip is crucial for project success, whether you’re an engineer, product designer, or procurement manager. This 2025 tutorial provides a clear roadmap to make informed decisions.

Key Takeaways:

- Define Your Application Requirements: Clearly outline your project needs—whether red-blue wavelengths (660nm, 450nm) for optimized plant growth or high-CRI (90+) full-spectrum chips for eye-friendly lighting. Understanding the specific demands of your application will help you select the right LED solution.

- Determine Technical Requirements: Align technical specifications such as power (ranging from 0.2W to 100W), voltage, and current (e.g., 3.2V at 350mA), and color temperature (3000K for ambiance, 5000K for precision). Assess environmental factors like heat and humidity, while considering key aspects such as brightness, CRI, and thermal management to guarantee optimal performance.

- Evaluate Suppliers: Choose reliable suppliers known for quality products and strong support. Strike a balance between budget and performance, test samples to ensure compatibility, and work with trusted industry leaders to guarantee quality and reliability.

In 2025, LED technology is transforming industries. Innovations like ceramic LEDs and high-efficiency chips (up to 170 lm/W) have reduced costs by 10% over the last five years, making high-performance lighting more affordable. For example, a greenhouse client adopted our high-efficiency chips, cutting energy expenses by 15% and boosting crop yields by 10%. These breakthroughs offer brighter, more sustainable solutions across automotive, horticulture, and industrial sectors, delivering unmatched value in today’s market.

This is your moment—act now! Discover how we operate and deliver top-quality solutions on our About page. Contact us at info@siroelectronics.com or visit our Contact page to discuss your LED chip requirements with our expert team. We’re here to guide you every step of the way.

Stay tuned for our 2026 update, where we’ll explore the latest trends and technologies in LED chips to keep you ahead of the curve.